Do you want to be informed on new Posts on this Thread? (members only)

| S&S Swan Maintenance - Mast corrosion on 47/069 |

|---|

|

Join Date: 29 January 2007

Posts: 1033 |

||

|---|---|---|

|

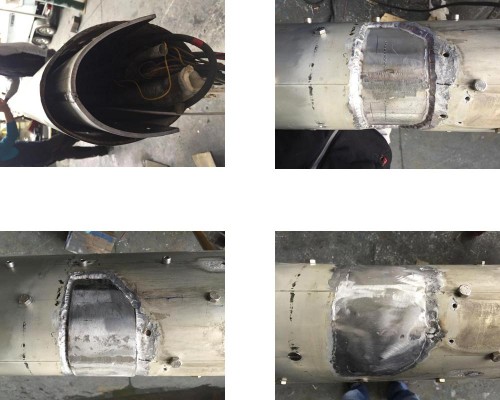

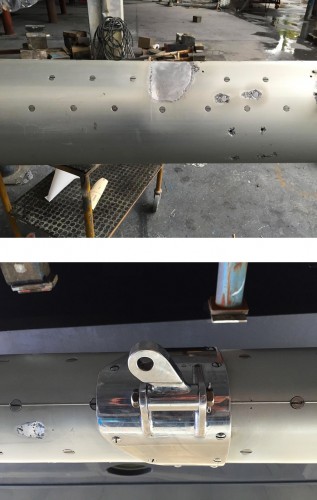

Mast corrosion on 47/069  From top left: 1 - corrosion, 2 - corrosion cut away, 3/4 - two views of the inside aluminum back plate  From top left: 1 - back plate inserted, 2 - back plate welded, 3-  As it is now, welded and screwed, looks perfect and perfectly tough!! |

|

Join Date: 01 July 2010

Posts: 48 |

||

|---|---|---|

|

...welcome to the club, Matteo!

|

|

Join Date: 01 April 2007

Posts: 106 |

||

|---|---|---|

|

dear all, after several posts on the forum about galvanic corossion, I removed my boom fitting on the mast. see picture. next thing is to remove the spreader fitting. will keep you informed......

jan yulunga 38/110 |

|

Join Date: 29 January 2007

Posts: 1033 |

||

|---|---|---|

|

Dear Jan, it’s bad of course, but could be fixed. In case you need more and detailed pics about the reparation I did on Vanessa’s mast, please let me know. Fai winds Matteo (47/069 Vanessa) |

|

Join Date: 01 April 2007

Posts: 106 |

||

|---|---|---|

|

Dear Matteo, Thank you for your encouraging words ! I would very much appreciate your information/photo's of your mast repair ! kind regards, jan

|

|

Join Date: 29 January 2007

Posts: 1033 |

||

|---|---|---|

|

Dear Jan, no problem, I am traveling today but back home later tonight and I will send you more and detailed photos. Anyway when I found out the corrosion on Vanessa’s mast (March 2015), as you can imagine, I was very disappointed, and scared to death, so I consulted Franco Manzoli, who is not just a good friend of mine but even (in my opinion) the best mast maker in Italy, and by the way he owns a share on a Sparkman&Stephens Swan 41! So, he knows his job and S&S Swan!!! He perfectly advised me, and I exactly followed his suggestions (pls see above description of the job). As you can see the mast (which I did now want to change, I am absolutely convinced nobody’s build today masts as perfect as the Nautor built ones -with the unmatchable help of Rod Stephens-‘ ) is now back on its place and as strong as new! So, don’t worry, you will fix it! Fair winds matteo (47/069 Vanessa) |

|

Join Date: 07 October 2014

Posts: 74 |

||

|---|---|---|

|

whow, that looks serious. tank you all to share what you found under your stainles steel fittings. doing next days my whole rigging and thought sailing will not to be so far - now i am scared to look under my ones. hope all is fine! fair winds, stefan |

|

Join Date: 02 February 2007

Posts: 202 |

||

|---|---|---|

|

Dear all S&S Swan fans, I would like to add a few comments on the above. To my opion it would be quite essential to try to isolate as much as possible the stailess steel of various pieces from the aluminium of the mast, especially since the anodisation has been destroyed by welding in what you describe. What I did on our Soeur Anne spreader fixings was to paint the surface with epoxy (2 coats at least) and adding silicone mastic before putting the stainless steel piece back in place. (Probably a polyurethane mastic would have been better.) Anyway, all this so as to avoid as much as possible salt water coming in between auminium and stainless steel. There is a link in the forum in which the professor gives this recommendation. All the best, Philippe 41/022 |

|

Join Date: 29 January 2007

Posts: 1033 |

||

|---|---|---|

|

Dear Friends, of course Philippe is correct, alluminum and stainles steel MUST be isolated, there are a few very good products, one is Tefgel (the one I used) and another one is Duralac. By the way I am attaching two more pics, the two last ones, which show final result. The job was a bit complicated of course, but dear Stefan, please don't worry, I am sure your mast could be repaired and will be as strong as it was when built. I think all of us S&S Swan Owners should check our masts under the stainles fittings...! Fair winds matteo (47/069 Vanessa)  |

- Threads : 1715

- Posts : 10273

- Members: 823

- Online Members: 0