Do you want to be informed on new Posts on this Thread? (members only)

| S&S Swan General - Replacing alloy toe rail for teak |

|---|

|

Join Date: 10 January 2016

Posts: 12 |

||

|---|---|---|

|

Replacing alloy toe rail for teak Hi, We are thinking about biting the bullet and replacing the alloy toe rail with a teak one. Realise the rail has a huge amount of bolts that are no doubt well corroded in, heard that some Swans have cut off the top flange and bolted or attached the new teak rail to the cut off sectioned alloy rail, but would be concerned about long term corrosion setting in.

Anyone carried out this job and if so any idea of how long it will take, also appreciate will need to dissmantle the interior.

Any photos out there??

Cheers

Jonty Sleeper X oaktree.layfield@gmail.com |

|

Join Date: 29 January 2007

Posts: 1033 |

||

|---|---|---|

|

Dear Jonty, alluminum toerail is structural part of our S&S Swan, I know of at least a S&S Swan Owner who got rid of the original toerail, installed a new one (carbon fiber, designed and engineter by a "top expert engineer"), and have now serious problem of cohesion between deck and hull. My opinion: do not do it. Our Professor will be more technical of course, and we are looking forward to his words. Fair winds matteo (47/069 Vanessa) |

|

Join Date: 02 January 2008

Posts: 1547 |

||

|---|---|---|

|

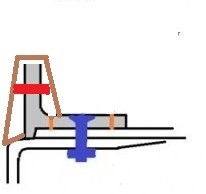

Dear Jonty The hull to deck joint should preferably remain bolted together, and the existing bolts can take care of this. It is suggested you leave them, this saves a lot of work.

Then there are two possible approaches

- either use a hole saw for cutting out an aluminium washer around each bolt, and finally lift off the rail without washers, or

- cut off the vertical toe rail flange with a vertical saw cut where the vertical flange radius begins outside the bolts. This leaves most of the horizontal flange in place.

The wooden rail should enclose the remaining aluminium parts completely, and have a lip on the outside, meeting the hull edge, To be bolted down with 400 mm spacing.

You may also need to look at the stanchion bases, and how to drain water from the deck.

Corrosion can be prevented by treating the underside of the wooden rail with epoxy, putting a thin sheet of plastic between the aluminium and wood, and filling all voids with mastic.

Would it help if I make a sketch?

Kind regards

Lars

|

|

Join Date: 31 July 2007

Posts: 88 |

||

|---|---|---|

|

I built a 37 ft boat many years ago. The hull - deck joint was similar to what our vintage Swans have, in that there is a flange on the hull, the deck is solid glass where it attaches to the flange and the core of the deck starts a little inboard. I used 5200 on the joint and bolts every 12 inches. Then I installed a teak rail, thru bolted with bolts every 12 inches so that I ended up with a bolt every 6 inches. And then I left it to cure. If you disturb the joint - as you plan to do - there is the risk of rupturing the joint. The deck and hull form a box and you can visualise the condition by taking a shoe-box and twisting it with and without the cover. When your boat is hauled out and sits in a craddle you can not tell what stresses are on the hull and what might happen when you go into the hull-deck joint. Also, at the time I could buy teak 20 feet long, so I had only one joint. My Swan has three joints on each rail. |

|

Join Date: 05 August 2010

Posts: 164 |

||

|---|---|---|

|

Dear Lars and others, yes I think a sketch drawing would be very welcome. It seems that corrosion on the aluminium toerail is not a singular event; I have seen the topic before and I can see our own toerail as well. If anything comes close to being a "common" problem on our boats, this would be a candidate, I think. So if you can add a sketch to the enormous treasure chest this forum is for future solutions, please please do. Humbly, |

|

Join Date: 02 January 2008

Posts: 1547 |

||

|---|---|---|

|

Dear Martin Here a sketch to start with. Kind regards Lars |

|

Join Date: 29 January 2007

Posts: 1033 |

||

|---|---|---|

|

Dear Friends, Lars and Martyin just sent me a fabolous document they worked on together, with full instruction on ho to do the job in the correct way. You can find the document on the "manual" section, under "maintenance". Of course this part of our website is accessible only by S&S Swan Association full Members. Thanks a lot to Martin and Lars! Fair winds! matteo (47/069 Vanessa) |

|

Join Date: 27 August 2014

Posts: 17 |

||

|---|---|---|

|

I have NOT done this ... but have been thinking about it as well.

My thought has been to cut the "rounded" top off the aluminum rail and thru-bolt and epxoy the teak onto the remaining vertical part of the aluminum toerail structure.

Any thoughts on this approach versus the professors?

Larry  |

|

Join Date: 05 August 2010

Posts: 164 |

||

|---|---|---|

|

Dear Larry, thank you for the idea and the request for comments. I am not sure we will ever get to an ultimate solution, so I find any new input interesting. My first impulse to cutting away the round top was "but why would you do it?". That top is the part of the rail that is normally maybe a bit scarred but free of corrosion, and corrosion would be my primary (and only) reason to work on the toerails. If the rest of the rail is free of corrosion, you might as well keep it. If it is not free of corrosion, and you still keep it but cover it with teak, my main concern is that you simply transfer ugly (=visible) corrosion into veiled (=invisible) corrosion. Stopping the corrosion is difficult enough in small areas, and getting epoxi to stick to aluminium is too. Interesting topic, in any case. Best regards, |

|

Join Date: 20 March 2016

Posts: 16 |

||

|---|---|---|

|

My "two cents" and humble opinion is: take down the head liners ONLY where the corrosion is ( and can ALL be seen ) once you have ALL the stanchions off and the stanchion bolts ONLY in regard to the stanchions) ) . Then : 1.clean out and grind out ALL the major corrosion . 2 Then use a carbon fibre ? kevlar two pot expoxy to bridge between the the good areas. (Lars or someone with EXPERT knowlegde eof what products woud be best to use would be paramount here).I would contact west systems or similar .There must be a high tech product that has exceptional strength on the market that can be used here and then fairing compound over that (if need latter) ? 3. Then obvously fair . 4. Protect what you have (is paramount) with etching compound .then tow pot highbuilds (and fair ) Then decide what finishes you are goind to use on the rail . Awl Grip etc (what is the HARDEST marine paint on the market/) Lars ? Matteo ? (you will obviously need to make sure each coat is compatable with the following coats before hand) 5.Then decide if that is aesthically OK. This path naturally finished here IF there are no stuctural issues re the L shaped longitudinal Al "Beam". 6 . Personally I think the teak covering would look far FAR better than the AL toe rail. from an Aesthic pointo of view and goes withe the Swan "look". I would be very interested to know from Lars or Matteo and others why S and S did not go withe a teak toe rail in the first place. Make sure you STOP salt water sitting on top of the bolt heads on the rail (that is THE problem IMHO) .There should of been a plastic ? washer etc between the blots and teh Al rail ?. Maybe fill up OVER the S/S bolt heads with epoxy? . Lars Matteo . what are your or others thoughts on this ?

Obviously replave ALL crappt bolts nuts etc with New Ones and use Anto corrosion greas etc under neath and on the threads . imho

Thankyou and all the best .I would be very interested in pics etc as you proced with thsi job.

Lats drawings are excellent. I wonder if you could tack weld short Al "spaces" as well on the flat flanges? Lars ?

Fair winds

|

|

Join Date: 29 January 2007

Posts: 1033 |

||

|---|---|---|

|

Dear Diogenes, thanks for your message. I think they both wanted the toerail to last as long as possible. A teak one would have not been so strong as the alluminum one, and honestly I can tell you most of the corrosion which you can see in those 35/40 years old anodized Nautor built toerails are more superficial (cosmetic) than structural. Which make me think they did choice the right way! That's my personal opinion. Fair winds! matteo (47/069 Vanessa) |

|

Join Date: 02 January 2008

Posts: 1547 |

||

|---|---|---|

|

Dear Diogenes Many of your questions have been discussed in an earlier thread. pls see

https://www.classicswan.org/forum/post_thread.php?thread=1977

A few comments to your last post

2. Do not use carbon fibre together with aluminum, as this will cause galvanic corrosion. Good adhesion is paramount here, and WEST should be able to advise.

4. Awlgrip is considered the longest lasting marine paint.

6. Actually the five first Swan models have teak toe rails, i.e. the Swan 36, Swan 43, Swan 40, Swan 55, and Swan 37 (except for the 4 last hulls). Sums up to a total of 280 yachts.

Aluminum rails were considered more practical because of the convenient attachment points provided by the many rail holes.

Newer Swan models have plastic washers between the bolts and the rail.

You are right - preventing water from reaching the bolt heads will eliminate galvanic corrosion.

You can not tack weld to the rail while in place, and the anodization must be removed completely in the weld area before welding.

Kind regards

Lars

|

|

Join Date: 20 March 2016

Posts: 16 |

||

|---|---|---|

|

Yes, that is what I have experienced too. The issues on my toerail were caused by saltwater sitting in the heads of the S/S screw tops but I solved that issue permanently. I also found that salt water and rainwater with sait residue wahing off the decks was collecting arouund the lowest point of drainage on the toe rail around the entry stanchions and gate area so I drilled out the holes in the toe rail lower in those areas so the rail drains now .

Thnbks so much Matteo.for all your work and dedication to these yachts and so many owners over the years. You truly are awesome :D I am buying a property in southern Italy and hope to be abvle to help out and crew for those in the Naples Amalfi coast area. |

|

Join Date: 20 March 2016

Posts: 16 |

||

|---|---|---|

|

Thanks Lars for the detailed reply , especially the information regarding carbon fobre and Al . ""You can not tack weld to the rail while in place, and the anodization must be removed completely in the weld area before welding""

Lars , I am just wondering why you don't recommend tack welding the rail while in place. Is it because of the possibilty of heating up the fibreglass laminate ? and affecting the structural integrity of the laminate under the rail? Do you think West systems is the best for filling in the totally corrodded away areas under the rail? or is there a better product or method?

Thankyou so much for your lifes work .

Another question I have is the old "stuck blakes thru hulls". I have managed to get every single one working again, cleaned reseated and greased , EXCEPT the one that discharges sink water under the galley on the port hand side (its hard to get too as well) . Looking on Youtube I cannot find much info on unsticking thruhulls that have "welded together" throug galvanic activity. I am seeing people unfreeze galvanic welded bolts using: Heat and parfin wax , Heat and then pouring water over the bolts or using automatic transmission fluid and acetone 50/50 mix. I am wondering what your, Matteos and others thoughts are .

Thankyou |

|

Join Date: 02 January 2008

Posts: 1547 |

||

|---|---|---|

|

Dear Diogenes It is likely that welding would heat up the adjacent laminate so much that the polyester resin breaks down.

For filling the recesses you could also consider a "liquid metal" like Belzona. Check the surface preparation recommendations for the products of interest, aluminum is a demanding substrate.

For the stuck Blake the recommendation is to cool the center spindle with dry ice, this causes it to shrink in relation to the body.

Kind regards

Lars

|

|

Join Date: 01 February 2007

Posts: 57 |

||

|---|---|---|

|

In 2006 I bought my 1972 Swan 40 which had an original varnished teak toerail. In 2007, as part of a major refit at Walsteds in Denmark, the deck and toerail were replaced. Walsteds proposed to leave the toerail unvarnished. After 11 years it still looks fine though some of the softer fibres in the wood have been washed out. No doubt varnishing would extend the life of the wood but require a lot of maintenance. How many years might the unvarnished toerail last ? (Of course there can be no precise answer to this question but any thoughts would be welcome) |

|

Join Date: 22 May 2016

Posts: 13 |

||

|---|---|---|

|

On corroding toe rails and other things, anodes for example. I have a 57 from 1982 and the toe rail is okay, despite the tremendous amount of "bad-electricity" introduced over the years after leaving the yard. I have cleaned out three garbage bags of bad cables. Any how, shore power will introduce electrical currents causing galvanic corrosion, it is complicated to explain exactly how it works but it is a fact. The remedy however is simple, install a separating transformer (for. example a Victron) and the problem is solved. If you chose a particular one, input can be 110 as well as 220 volts. |

|

Join Date: 31 July 2007

Posts: 88 |

||

|---|---|---|

|

On corroding toe rails and other things, anodes for example. I have a 57 from 1982 and the toe rail is okay, despite the tremendous amount of "bad-electricity" introduced over the years after leaving the yard. I have cleaned out three garbage bags of bad cables. Any how, shore power will introduce electrical currents causing galvanic corrosion, it is complicated to explain exactly how it works but it is a fact. The remedy however is simple, install a separating transformer (for. example a Victron) and the problem is solved. If you chose a particular one, input can be 110 as well as 220 volts. In 1991 I bought 040/012 and I have the original wood rails. They were varnished and that is a lot of work. Left bare, the teak will weather away at a rate of about 1/16 inch per decade. During my ownership I would have lost about 3/16 inch and on some of the wooden cleats it shows. I have been using Starbrite Tropical Teak Oil Sealer made by Star brite, Fort Lauderdale FL The consistencey is about like mustard, that makes it very easy to apply. It lasts several years. My last coating was about 2012 and I should put some more on. Very little sanding - just remove the dirt using sandpaper. It does not flake off. It is probably a stain. It protects the teak and looks very acceptable. On my Blake seacocks I adjust the bolts so that the handle is easy to turn but not so loose that it leaks. It is a very fine line. The 1 1/2 size is more difficult to adjust. It takes a 15 mm open end wrench. I should take them apart and lubricate them again using waterproof grease. The last time I did it about 20 years ago but I check them about once a year. If you adjust them too tight, you can move the handle for a few days and then it becomes stuck. I find the cover plate can wiggle a little and they do not leak. It does not help that they are mostly difficult to access and it does become more difficult the older I get. The 40 is a delightful boat to sail. Between myself and the autopilot we can handle it by ourselves. That has become very important as my friends and crew are dying off and I am getting more peculiar and want to be alone. |

|

Join Date: 10 January 2016

Posts: 12 |

||

|---|---|---|

|

Hi,

Is it possible to purchase new alloy toe rails, realise it is a big job and would have to take out some of the internal furnitiure, the problem is the rail is alloy and bolted down with S/S bolts and will be a big job to remove and replace, we like the alloy rails as is traditional and very strong.

Any clues as to where we could purchase some rails?

Rgds

Jonty |

|

Join Date: 10 January 2016

Posts: 12 |

||

|---|---|---|

|

Dear Jonty, alluminum toerail is structural part of our S&S Swan, I know of at least a S&S Swan Owner who got rid of the original toerail, installed a new one (carbon fiber, designed and engineter by a "top expert engineer"), and have now serious problem of cohesion between deck and hull. My opinion: do not do it. Our Professor will be more technical of course, and we are looking forward to his words. Fair winds matteo (47/069 Vanessa) Hi Matteo,

We will take your advice.

Jonty |

|

Join Date: 29 January 2007

Posts: 1033 |

||

|---|---|---|

|

Hi Jonty, you can buy a complete set from Nautor in Finland. Fair winds! matteo (47/069 Vanessa) |

- Threads : 1715

- Posts : 10273

- Members: 823

- Online Members: 0