Do you want to be informed on new Posts on this Thread? (members only)

| Sail & Rigging - Renewing Swan 431 rods with dyform / wire? |

|---|

|

Join Date: 06 January 2012

Posts: 67 |

||

|---|---|---|

|

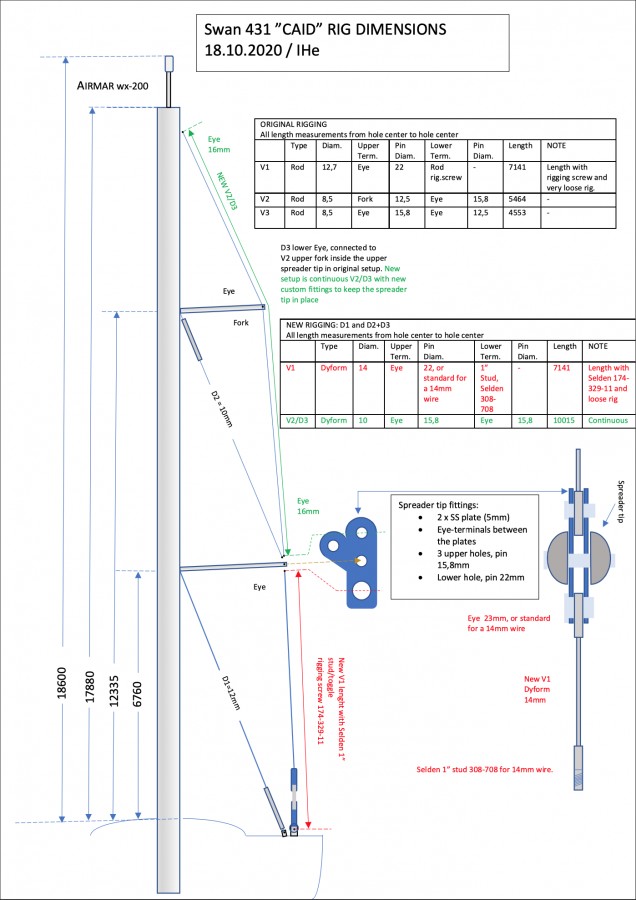

Renewing Swan 431 rods with dyform / wire? Hi You all Swan lovers! We've planned to renew the still remaining rods with wire or dyform this winter. They've been inspected and the heads renewed about ten years ago by the PO. Many have said that it'll be quite difficult have the rod ends hydraulically cold pressed here (in Finland). So, with wires then. What we have now is below (shroud, type, BS in kgf) and all are independent shrouds. V1: 12,7mm rod, 17.200kgf V2: 8,5mm rod, 8.000kgf D3: 8,5mm rod, 8.000kgf D2: 10mm 1x19 wire, 7.250kgf (renewed 2010) D1: 12mm 1x19 wire, 10.400kgf (renewed 2010) They all exceed the minimum breaking strenghts (described at the S&S sail plan) with a good margin.

Our plan: V1: 14mm dyform, 19.300kgf V2/D3: one lenght 10mm dyform, 9.700kgf. With this setup we're able to use all the existing spreader tip fittings, etc and the rigging stays at least as strong as it was. We just have to lock the upper spreader ends to the new V2/D3:s, but thats already solved. I also just happen to have a pair of new Selden 1" stud/toggle rigging screws already acquired. One size too big, but with the help of some hole reducersleeves they fit to the existing chainplates without any hassle. The total material price of this project (wires, end fittings, pins, but without the rigging screws) will propably be a bit over 2000,- euros according to two offers I've gotten from professionals from Finland and Holland, not bad! Questions: - why not to continue with this plan? Any weak spots? - what was the original idea of Nautor to use 12,7mm rod for the V1 as it is very strong compared to D2 and V2 which continue from the first spreader tip this V1 ends? - How do the loads spread from the V1 to and between the V2 and D2? - what is the correct tension for the D2:s and how to set it before the mast is raised again next spring? BTW I tested it with mast already lowered horizontal to the ground. I tensioned the main shrouds as tight as I could with some pulleys to measure the actual shroud lenghts. The D2:s just begun to tighten when the V1:s were already quite tight. Not a very scientific approach but the best at that time.

Soon (?) will we be sailing again!

IHe, S431-12, Finland

|

|

Join Date: 06 January 2012

Posts: 67 |

||

|---|---|---|

|

Here are the rig measurements if they are of any use to someone else. IHe  Swan 431 rig dimensions |

|

Join Date: 30 January 2007

Posts: 462 |

||

|---|---|---|

|

Hi You all Swan lovers! We've planned to renew the still remaining rods with wire or dyform this winter. They've been inspected and the heads renewed about ten years ago by the PO. Many have said that it'll be quite difficult have the rod ends hydraulically cold pressed here (in Finland). So, with wires then. What we have now is below (shroud, type, BS in kgf) and all are independent shrouds. V1: 12,7mm rod, 17.200kgf V2: 8,5mm rod, 8.000kgf D3: 8,5mm rod, 8.000kgf D2: 10mm 1x19 wire, 7.250kgf (renewed 2010) D1: 12mm 1x19 wire, 10.400kgf (renewed 2010) They all exceed the minimum breaking strenghts (described at the S&S sail plan) with a good margin.

Our plan: V1: 14mm dyform, 19.300kgf V2/D3: one lenght 10mm dyform, 9.700kgf. With this setup we're able to use all the existing spreader tip fittings, etc and the rigging stays at least as strong as it was. We just have to lock the upper spreader ends to the new V2/D3:s, but thats already solved. I also just happen to have a pair of new Selden 1" stud/toggle rigging screws already acquired. One size too big, but with the help of some hole reducersleeves they fit to the existing chainplates without any hassle. The total material price of this project (wires, end fittings, pins, but without the rigging screws) will propably be a bit over 2000,- euros according to two offers I've gotten from professionals from Finland and Holland, not bad! Questions: - why not to continue with this plan? Any weak spots? - what was the original idea of Nautor to use 12,7mm rod for the V1 as it is very strong compared to D2 and V2 which continue from the first spreader tip this V1 ends? - How do the loads spread from the V1 to and between the V2 and D2? - what is the correct tension for the D2:s and how to set it before the mast is raised again next spring? BTW I tested it with mast already lowered horizontal to the ground. I tensioned the main shrouds as tight as I could with some pulleys to measure the actual shroud lenghts. The D2:s just begun to tighten when the V1:s were already quite tight. Not a very scientific approach but the best at that time.

Soon (?) will we be sailing again!

IHe, S431-12, Finland

Dear IHe, Lars already replied to the important questions but maybe he did not stop your curiosity. I can reply to one of your questions that regards the parting of the tension coming from V1 and passed to V2 and D2. If V2 and D2 would depart from the alignment with V1 of the same angle (which are obviously NOT), both V2 and D2 would ideally get half of the resulting tension which - surprise! - may be even larger than the tension on V1; as D2 is not aligned, while V2 is nearly so, V2 will take something more of 50% and D2 something less. The amount can be computed exactly applying a physics law but here it does not really matter. Nautor (or the designer) knew it but had also to consider the available wire/rod sizes so decided for the ones you found: D2 slightly less strong than V2. As the wires/rods are always oversized, you will not find that the "breaking strengths" obey exactly the mentioned law but they are always well within the limits. Besides the breaking strengths, as Lars stresses also the stretch of the different branches is of paramount importance for the above computations. Daniel, Luna Menguante 411/004 |

- Threads : 1715

- Posts : 10273

- Members: 823

- Online Members: 0