Do you want to be informed on new Posts on this Thread? (members only)

| S&S Swan General - Swan 57 007 structural refit |

|---|

|

Join Date: 17 July 2020

Posts: 104 |

||

|---|---|---|

|

Swan 57 007 structural refit Hi all, as I already put some pictures and begin to exchange on the net on Facebook and Instagram, I decide to put more in this forum... I just bought the Swan 57 007, now named Algol V and French flag, ex Macobi (USA), ex Flyer (USA and Dutch). this boat raced a lot from 1979 to 1992, most in Pacific coast of USA, and then sailed a lot as a part of a sailing school between England and Brittany. The survey before sale did not notice any structural problem, just some cracks at front and aft of keel, not mentionned to be important, and corrected by last owner before delivery. But I wanted to be sure and had planned to check more deeply this when starting a big refit in Badalona. It did not take long to find more when taking the boat ashore, as the cracks had come back at aft of keel after sailing from Brittany to Spain, and the keel showed some flexibility from left to right, and up down at aft... So we decided a huge ultrasound survey of the hull. And we found some delaminations at the junction between hull and false keel. the bottom of bilge (and the keel bolts) were only joined to the hull shell, and no more to the structural parts inside the boat... The repair process decided by Nautor (Lars Strom and EMV Marine) was to remove the central part of bilge and false keel and rebuild in new more strong materials. So the planning is : remove the keel - laminate a new external shell - block the new shell with external reinforcements - remove internal reinforcements - remove old shell by inside - rebuild internal shell inside - replace internal reinforcements - remove external reinforcements - replace keel As already read on the web and in this forum, I seem to be the 4e Swan 57 to have to make this structural refit, and as all the others the history of the boat as an accident (for 007 in 2014) but nobody is 100% sure the accident is really the only reason we need to do that... these boats are now close to 40 years old and all the 57 owners or buyers must have a deep look at the keel on their beloved 57's. I will now share some pictures of this refit in progress, and be glad to exchange with all, and as I am a new Swan owner, let me know if I should have another very close look somewhere else on my 57 ! Yves

Badalona - out of water Ultasound survey Keel removed |

|

Join Date: 17 July 2020

Posts: 104 |

||

|---|---|---|

|

after preparation, following steps : the external new hull external preparation external lamination external vacuum |

|

Join Date: 17 July 2020

Posts: 104 |

||

|---|---|---|

|

external reinformcements to keep the good shape internal removal internal external junction to remove the old hull part |

|

Join Date: 17 July 2020

Posts: 104 |

||

|---|---|---|

|

internal old hull removed |

|

Join Date: 17 July 2020

Posts: 104 |

||

|---|---|---|

|

the new hull begining from the inside, epoxi and 3D lamination internal new hull lamination internal vacuum process |

|

Join Date: 29 January 2007

Posts: 1033 |

||

|---|---|---|

|

Cher Yves, |

|

Join Date: 20 July 2017

Posts: 119 |

||

|---|---|---|

|

Dear Yves, thank you very much for your post, very detailed and informative ... and, for oher 57 owners like us, also a bit daunting, I suppose. Kairos is hull no 43 of 49 of the 57s built and my understanding was that only (mainly?) the first hulls built experienced structural problems. Believe this was then addressed for subsequent hulls by Nautor - however, as you are rightly pointing out, 40 years is a decent age - even for a well-built S&S Swan. While Kairos is showing no signs of a problem I might enquire with our yard about an ultrasound survey - better safe then sorry! Thanks again, fair winds Stefan Kairos - 57/043 |

|

Join Date: 02 January 2008

Posts: 1547 |

||

|---|---|---|

|

Dear Stefan Only one hull experienced structural problems in the keel area in the famous Fastnet Race 1979, but there were other 57s in the same race not having any such problems.

Nautor then decided to reinforce all 22 delivered 57s, and upgraded the construction of undelivered hulls from 023 onwards.

This can be verified on photos of the keel floors, but the tanks need to be removed for this.

I would suggest later problems are caused by grounding.

Kind regards

Lars

|

|

Join Date: 20 July 2017

Posts: 119 |

||

|---|---|---|

|

Dear Lars, thank you very much for your clarification, this sounds very reassuring indeed! Thanks again and all the best, Stefan Kairos - 57/043 |

|

Join Date: 17 July 2020

Posts: 104 |

||

|---|---|---|

|

Dear Stephan and Lars, yes all the concerned 57 had an accident in the past, grounding or like 57-007 falling from a travelift, and in this case the consequences are only appearing five years after… So if you know all the boat history and are sure the boat never grounded or something, no need to loose confidence in such a boat ! In all cases of delamination, it always seems to be in the same area, in the aft part of hull and false keel junction, and can be seen in the bilge with some cracks on hull between the battery racks, or when taking the boat ashore if you notice some little keel flexibility when suspended. if you dont notice anything, no need to launch an ultrasonic survey… Fair winds all ! Yves Algol / 57-007 |

|

Join Date: 17 July 2020

Posts: 104 |

||

|---|---|---|

|

here some updates from Badalona Yard second lamination end of second lamination third lamination and post treatment |

|

Join Date: 17 July 2020

Posts: 104 |

||

|---|---|---|

|

still updates from EMV Marine 4th lamination 4th vacuum |

|

Join Date: 17 July 2020

Posts: 104 |

||

|---|---|---|

|

and end of new bilge lamination... now have to put some more lamination in front and aft, and replace the reinforcements... finished reinforcements start |

|

Join Date: 17 July 2020

Posts: 104 |

||

|---|---|---|

|

continued... aft finished front finished internal reinforcements new foam |

|

Join Date: 17 July 2020

Posts: 104 |

||

|---|---|---|

|

continued... next updates in 2021 !!! internal reinforcements replaced external temporary reinforcements removed |

|

Join Date: 22 May 2016

Posts: 13 |

||

|---|---|---|

|

Thank you for reporting on this extremely interesting operation and do praise the people doing this excellent piece of work. Running an angle grinder in the bottom of a bilge is a gruesome experience. Just a quick note on Ultra Sonic Testing. My firm is using Ultra Sonic testing of Cast Iron and Lead in radio active applications. In order to get reliable results first the operator needs to be certified and should be able to exhibit a valid certificate. Second, the U-S device must me calibrated on a piece where discrepancies can be detected according to known descrepancies in the calibration piece. This is necessary in order to determine for example what a fairing from polyester/microbaloons on the inside of the hull will show up like in the U-S device. I do not doubt that in your case verything was done very well, but U-S testing is not simple so it could be a good idea to probe the practices a little before drawing conclusions. BRGDS Mats @Hermia II (Swan 57 #035) |

|

Join Date: 17 July 2020

Posts: 104 |

||

|---|---|---|

|

Of course UV calibration was done before testing by a well known surveyor ! some holes were made in the suspected areas… thanks for your help, I hope Algol will look as beautifull as Hermias in some time… Yves _ Algol V (Swan 57 #007)  |

|

Join Date: 17 July 2020

Posts: 104 |

||

|---|---|---|

|

Update on bilge woks Yves (Algol 57 007)  Central lamination  Front and mast step  Aft |

|

Join Date: 17 July 2020

Posts: 104 |

||

|---|---|---|

|

Hello all, lamination is finished and now painting to prepare to reintall keel  Lamination finished  Bilge repainted  New false keel !!! |

|

Join Date: 17 July 2020

Posts: 104 |

||

|---|---|---|

|

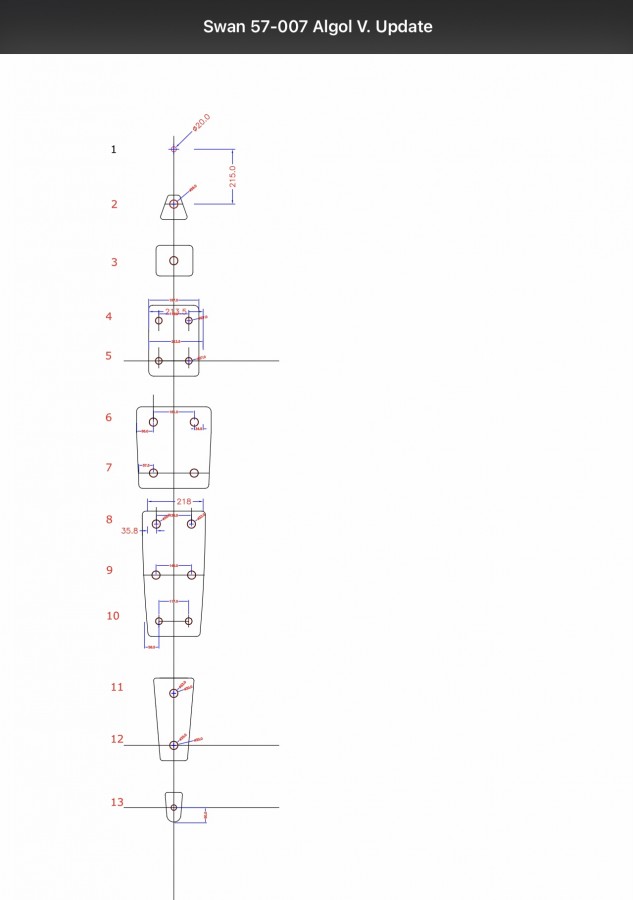

Keel plates and new holes ready !  New plates for keel bolts designed  And ready  And new holes in bilge |

|

Join Date: 24 April 2020

Posts: 18 |

||

|---|---|---|

|

The paint in the bilge looks amazing - may I ask what product / brand it is?

Thanks/Adrian Little Cygnus 47 048

|

- Threads : 1715

- Posts : 10273

- Members: 823

- Online Members: 0