Do you want to be informed on new Posts on this Thread? (members only)

| S&S Swan Maintenance - Exhaust connection problem Swan 41 Perkins 4108 |

|---|

|

Join Date: 11 July 2010

Posts: 3 |

||

|---|---|---|

|

Exhaust connection problem Swan 41 Perkins 4108 |

|

Join Date: 02 January 2008

Posts: 1547 |

||

|---|---|---|

|

Dear Gene I saw my name mentioned in the first posts on this subject, and would like to contribute with the following information: The original dry exhaust system with a rubber hose connected directly to the engine manifold would not be acceptable on new yachts today, The reason is that a rubber hose can not stand the highest exhaust temperatures. Perkins states that the maximum exhaust temperature for the 4.108 is 670 deg. C, and a silicone rubber hose can stand about half of that. Exhaust temperature is directly related to engine output, and based on the time span the hose has survived it is obvious that reduced engine outputs have been used most of the time, and the exhaust temperature did not rise to critical levels. If you prefer to continue with the dry hose it would, however, be advisable to install a temperature gauge on the exhaust in order to avoid excessive temperatures. It can also be pointed out that the ignition temperature for wood is about the same as the temperature limit for the rubber hose, and there are wooden parts very close to the hose. It is very likely that silicone high temperature rubber hose was used, will attempt to find out the original specification, the supplier was French. The new safety standards enforced by the CE-approval put emphasis particularly on the prevention of fire on board. From this point of view it would be advisable to change the first part of the exhaust to a wet system. The existing waterjacketed system in the locker could well be retained. If there is a rubber muffler just before the thru-hull connection it is preferable to remove it in order to reduce back pressure in the system. The wet system reduces exhaust noise very effectively, and a muffler is not needed. The wet system requires a water lock - a chamber with approx 10 litres capacity located so it always stays below the manifold even when the yacht heels. The water lock should be equipped with a drain cock. Kind regards Lars |

|

Join Date: 02 February 2007

Posts: 202 |

||

|---|---|---|

|

Hello Gene and dear Professor. With our 41/022 we obviously had the same problem as Gene. We first tried to obtain a new silicone rubber hose (produced by Spiragaine in France:there was still a sticker on a first spare we got from Nautor) but after three month discussion with Spiragaine and two tests on producing a spare we abandoned as the result was far too thin. Finally we went for a stainless steel flexible exhaust part we got from silenc'air in the south of France (see silencair.com for their catalogue in french). I beleive it is a US product, but could not find the producer in my files. We also: 1/ built an aluminium isulation jacket with a 3 to 5mm space behind, between wood or polyester all aroud. 2/ following a old recommendation from Lars we made sure there was maximum air sucked by the engine flowing around the exhaust (to cool it down) in increasing as much as possible the section of the wooden conduit, and also closing the pipe of the engine box fan when not in use. 3/ Finally we replaced part of the rubber pipe of the engine cooling water by stainless steel (additional cooling...) You can see how it looks in the attached picture: it was done during winter 2006/7 and still looks fine. Main difficulty: the flexible hose is 2", so we had to weld the right size pipes ad the end of the exhaust mainfold on the engine side, same on the other side. The juction collars are also supplied by the same company. The "step" is now cool, while it was getting rather hot with the rubber pipe. Hope this helps. Kind regards. Philippe  |

|

Join Date: 02 January 2008

Posts: 1547 |

||

|---|---|---|

|

Dear Philippe Many thanks for this helpful information ! Would you have a specification for the Spiragaine flexible rubber hose? It appears the company does not show a catalogue on their website. Best regards Lars |

|

Join Date: 02 February 2007

Posts: 202 |

||

|---|---|---|

|

Dear professor, the specifications I have are the following: inside diameter 50mm, length 500mm, thickness around 5mm. Material: silicone rubber armed with glass fiber(?) Despite Spiragaine's agreement to supply the original product, I got something exactly with the original aspect but only 2mm thick. Considering what had happened with the original product (burning rather quickly) I never dared mounting what I received! Also they apparently were never able to trace Nautor's original order. Could have come through a distributor?? Kind regards. Philippe |

|

Join Date: 11 July 2010

Posts: 3 |

||

|---|---|---|

|

We are desperately seeking a replacement solution for the connection between the exhaust elbow and the waterlock on our Swan 41. The connection must be flexible but able to withstand the hightemperatures of dry exhaust gasses and insulated to protect the surrounding area. I set forth below a copy of our message sent to Nautors on this problem. They respond that they do not know of any supplier for a suitable connection. Many thanks for any help you can provide. Gene Dye Swan 41 n° 043 "Jonah" I would like to thank all who have commented and even one former owner who called within two hours of the original posting. The advice from Lars is the same as that from Nautors which I mentioned. I have no doubt that this would be a preferable engineering soultion, but it involves rather extensive redesign and custom refitting of the entire exhaust and waterlock system, which is very expensive work. After all the various consultations, including several with Swan service yards, I have decided to repair the junction with a flexible stainless steel tube, along the lines of the repair pictured on the website in Philippe's thoughtful response to my message. I have located a supplier, AEV Flex, in France and they are supplying flexible stainless steel tubing made especially for engine exhausts with interior diameter 50mm and exterior diameter 55mm. As the engine elbow and waterlock are both of exterior diameter 48.5mm, this tubing will fit over and around both ends. We count on an overlap of 4cm on both ends with both end joints sealed with special high temperature resistant exhaust putty and clamped with two 50mm stainless steel "U" clamps. The tubing supplier confirms that in his view this will result in a durable and airtight seal on both ends. As a detail, in order to get the full overlap intended, we will have to loosen up the waterlock and slide it back to permit the fitting in place of the tubing. I also note that we will deal with the ambiant heat issue by wrapping the tubing with thick bands of fiberglass heat insulation. I already had two layers of this insulation around the temporary pipe pictured in my message, and it was very efficient (you could touch the outside of the insulation during motor operation). When this is all in place, I'll post a followup message to confirm the result. Again many thanks for all the advice. Gene Dye |

|

Join Date: 11 July 2010

Posts: 3 |

||

|---|---|---|

|

Dear PhilippeV: Apart from my general reaponse, I wanted to thank you personally for your response and picture. Best regards, Gene Dye |

|

Join Date: 02 February 2007

Posts: 202 |

||

|---|---|---|

|

Sorry if this is late thinking... I believe it is better to try and cool the exhaust as much as possible as there is a risk of heavy corrosion in the cooling sleeves on both sides (muffler, and engine outlet). Warm sea water eats stainless steel pretty quickly. We added zink anodes on both sides and they are eaten pretty quickly, but have seen no holes in the cooling sleeves so far... Kind regards. Philippe 41/022 |

|

Join Date: 02 June 2007

Posts: 43 |

||

|---|---|---|

|

What was Nuator thinking. I got so fed up of the noise from the original Swan 41 exhaust that I tore the whole thing out and replaced it with a waterlift on the aft cabin bulkhead and routed the exhaust next to the shaft log to the counter beneath the transom. I should also mention that I replaced the engine with a Volvo-Penta D2-55. The exhaust syphon break is installed on the foward side of the bulkhead in the locker behind the stairs. The result: much, much, much quieter, no parts to corode and I now have the old exhaust locker for storage. This system was installed in 2006 and has had no issues. I built a round veneered plywood cover (not shown) for the waterlift that fits beneath the mirror shelf and beautifully matches the existing woodwork style.

|

|

Join Date: 02 January 2008

Posts: 1547 |

||

|---|---|---|

|

The reason behind the use of waterjacketed exhaust systems in the beginning: During the first years of existence Nautor's thinking was very much along Rod Stephens thinking, wet exhausts were looked at with sceptisism, and were at the time rather unusual for sailing yachts. The first model to have a wet exhaust was Swan 38. Lars |

|

Join Date: 02 October 2010

Posts: 3 |

||

|---|---|---|

|

Plciadies, Can you or someone provide the size of the waterlift muffler and manufacture? I like your solution. |

|

Join Date: 02 June 2007

Posts: 43 |

||

|---|---|---|

|

kaleda It's a Naqualift wet exhaust. ST 300-1010 3" OD inlet & outlet. Exhaust hose is routed to the counter just under the transom. You will find this setup MUCH quieter than the stock exhaust and you will be able to use the old exhasut cabinet for storage. http://www.marineparts.com/mpf/mpf325.aspx |

|

Join Date: 25 March 2011

Posts: 1 |

||

|---|---|---|

|

I have the part, Naqualift ST-300-1010, mentioned by pleiades in his replies to this post. It is unused. My friend died before he could install it.

|

|

Join Date: 22 January 2023

Posts: 2 |

||

|---|---|---|

|

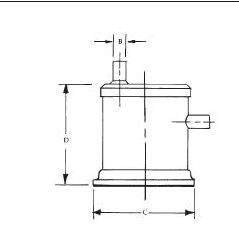

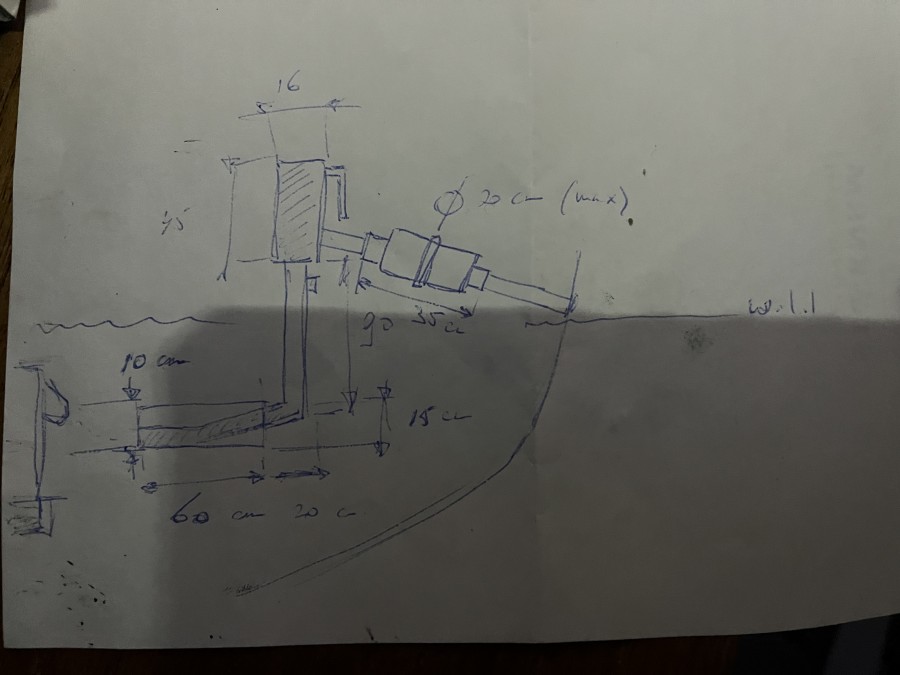

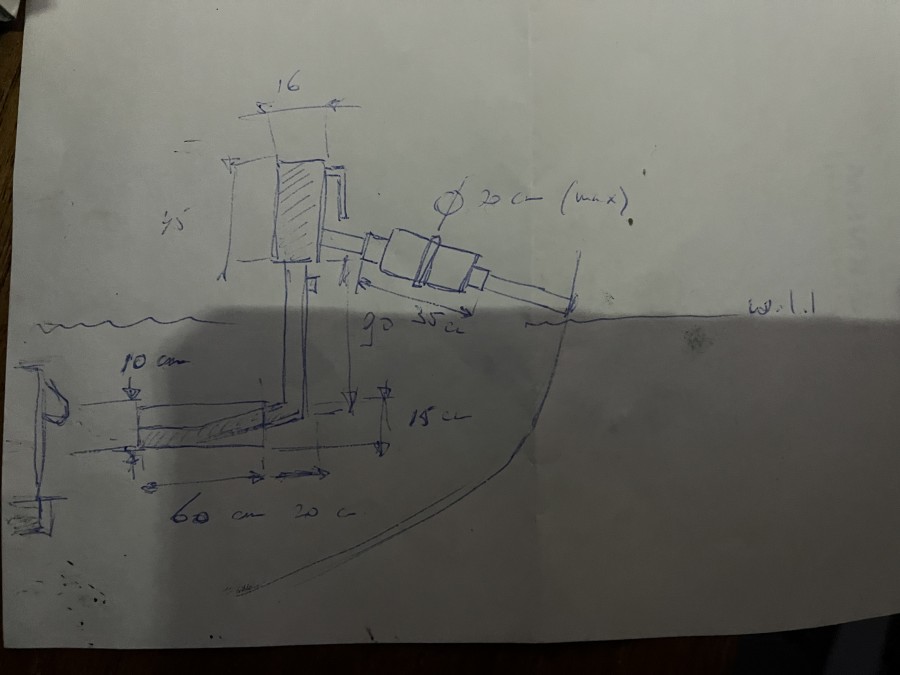

Dear Philippe Many thanks for this helpful information ! Would you have a specification for the Spiragaine flexible rubber hose? It appears the company does not show a catalogue on their website. Best regards Lars Dear all am busy installing a new engine to replace the perkins 4108. Question do you know how the internal chamber looks like of the vertical stainless pipe? Here was the initial coolingwater injection. On the new engine it's st the exhaust. Am wondering if an airbreather and waterlock at the bottom are needed.. kind regards Jantijs (0031612441651)  Muffler/ previous injection  Measurements  |

- Threads : 1715

- Posts : 10273

- Members: 823

- Online Members: 0