Do you want to be informed on new Posts on this Thread? (members only)

| Keel Bolts and General Topics on Keel - Swan 41 mast shoe (steel beam) |

|---|

|

Join Date: 27 January 2019

Posts: 6 |

||

|---|---|---|

|

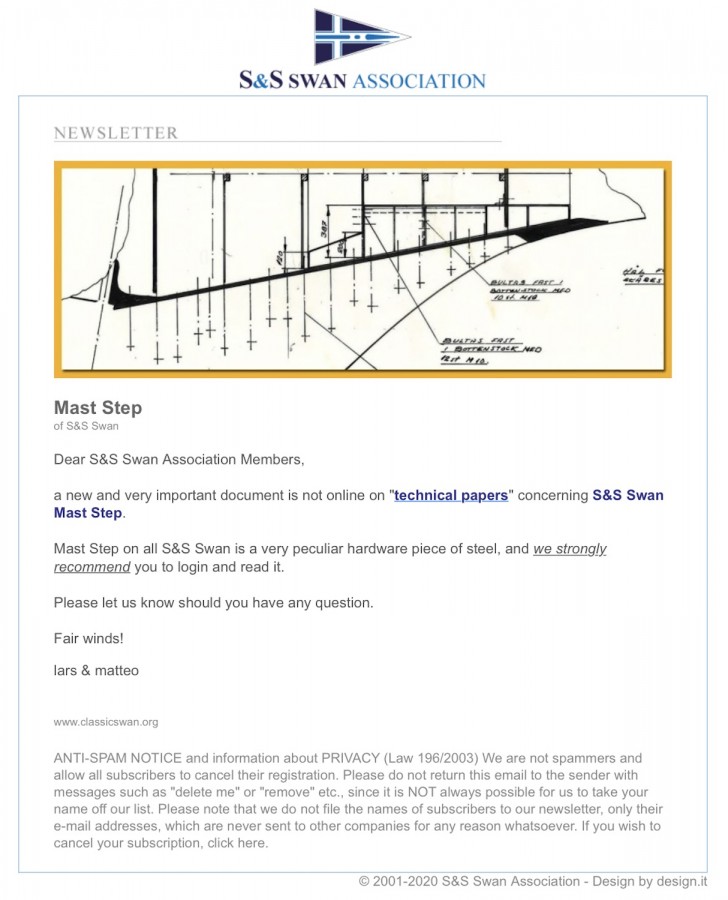

Swan 41 mast shoe (steel beam) Hello! I am still refitting my "new" Swan 41. I am enjoying it very much. I am writing about the massive steel I-beam that the keel is attached to. We all know this structure. Not surprisingly, mine is corroded. The fibreglass tabbing over the lower plate and keel bolts lifted over time and rust accumulated and blocked the drainage holes leading to further rusting and blocking and so on. I would like to remove this for inspection and refurbishing or replacement as required. I have discussed this with the professor and I feel like I have a reasonable understanding of the task. What I am asking about are the practical aspects of this job. What is the best (most effective yet safe) way to lift this steel off the hull? Does it come off easily? If anyone has done this, has there been damage to the hull as a result that required repair? Fortunately, the 41's forward beam does not traverse any major bulkheads so the fibreglass part is not so challenging. Thank you, Matt - Swan 41/053 |

|

Join Date: 20 October 2009

Posts: 3 |

||

|---|---|---|

|

Hi, This may be a little late regarding Matt´s question, but assuming this is a common issue in our boats, I would like to share my experience. Last winter, with valuable advice from Lars, we had the mast foot steel beam of our 41 removed and refurbished. As Matt described, the drainage holes were blocked over time with rust and dirt in the bilge. Biggest job is removing the fiberglass tabbing covering the bolts and lower flange of the steel beam. Once this was done, the beam came off quite easily in our case. It was then lifted out of the boat, blasted clean of corrosion and painted with two layers of epoxy-based industrial paint (re-galvanizing would be the "correct" restoration, but protective paint could be done at the yard). It´s a good idea to sand the bilge, check the bulkhead and floor laminates and repaint with topcoat, when the beam is removed. Below a couple of pictures. Best, Riku (41/003) Before Steel beam refurbished Re-installed, almost ready |

|

Join Date: 29 January 2007

Posts: 1049 |

||

|---|---|---|

|

Dear Riku, |

|

Join Date: 29 January 2007

Posts: 1049 |

||

|---|---|---|

|

Dear All,  |

|

Join Date: 27 January 2019

Posts: 6 |

||

|---|---|---|

|

Hi Riku: Thank you very much for your reply. In fact it is not too late. Our refit trajectory is slow and steady and I did not make the decision about the mast step yet. Interestingly, I did not have a problem with the tabbing. I can access all the bolts. I was able to shave off the loose / excess fibregalss tabbing over the lower flange of the beam. What technique did you use to pry the steel off the hull? The yard here is worried about damaging the hull. I would very much like to remove and refubish this as you have done. I will probably have more questions when it comes time to put it back in. Thanks again,

Matthew Swan 41/053 |

|

Join Date: 20 October 2009

Posts: 3 |

||

|---|---|---|

|

Hi Matthew, In original installation the steel beam is "glued" in place only by placing it on wet resin, the bond should be weak. I believe the yard used wooden wedges to loosen the beam. Best regards, Riku |

- Threads : 1729

- Posts : 10335

- Members: 832

- Online Members: 0